RFID Readers For Retail Inventory Management

Using RFID reader for retail inventory management can make tracking high-value items easy and accurate and eliminate human error. However, these systems are best used for tracking items with a long life, such as expensive products.

RFID improves accuracy by eliminating human error

RFID improves accuracy by eliminating human error

RFID reader for retail inventory management are an efficient and cost-effective solution to enhance accuracy and reduce stock management costs. The technology eliminates the risk of human error and ensures timely stock turnover. These solutions can help retailers improve efficiency, increase productivity and reduce costs, thereby improving margins.

RFID is an excellent solution for various industries, including retail, manufacturing, warehousing and distribution, and supply chain. It offers numerous benefits, including reduced inventory shrinkage, improved asset tracking, and improved merchandising.

RFID can also help improve production and inventory accuracy, reducing downtime during peak periods. Additionally, it can assist in detecting missing or damaged items in the production line. Likewise, it can also provide real-time inventory data to inform merchandising decisions.

In one study, RFID improved storage accuracy by as much as 75%. In another, it reduced shrinkage losses by as much as 15 per cent. RFID enabled a leading Australian swimwear brand to minimise out-of-stock situations, increase sales, and speed up fulfilment.

When choosing a technology solution provider, finding one with expertise in the retail industry is essential. It can help retailers refine existing processes, improve operations, and develop new business processes.

RFID can also reduce stockouts, a significant challenge in many retail environments. In addition, RFID helps decrease time and labour spent on inventory and allows staff to focus on providing excellent customer service.

RFID is also a great way to enhance kanban, which allows warehouse operators to control shrinkage. For example, when inventory is low, RFID can trigger auto-ordering. Also, a fixed RFID reader can be placed around a perimeter of a monitored area, which can help to eliminate the need for manual intervention.

As a result, a company can maintain tight control of its assets, which is the easiest way to keep costs down. Similarly, RFID can help retailers track frequently moved items and avoid the costly process of replacing things that go missing.

RFID also improves the quality of goods. Unlike barcodes, which require workers to scan each object manually, RFID identifies each item through an automated process.

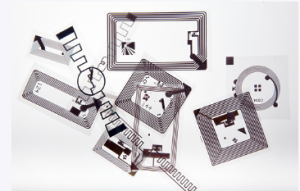

RFID tags can replace the barcode label

RFID tags are small tag chips that contain essential information about an item. They are usually applied to shipments and bulk packages and can provide more insight than a simple barcode.

RFID can help track inventory through the supply chain and reduce theft and shoplifting. It can also alert workers of attempted theft or when items are moved from a store.

RFID is a proven solution to retail inventory management, but it is still relatively new. However, its use is growing, especially in the consumer goods industry.

Despite their many advantages, some retailers are worried about the cost and time it takes to implement an RFID system. But if they can afford to, implementing an RFID solution could make them more productive, save money, and give them a greater understanding of their inventory.

There are several types of RFID tags, including ultrahigh-frequency (UHF) and low-frequency. The latter is better suited for tracking high-value inventory.

RFID has the power to tell you what items you have in stock, as well as what you might need to order. You might be surprised to learn that you can even automate reordering when you run out of a particular product.

Whether you’re a retailer or a supplier, consider using RFID to improve your supply chain efficiency. With the right tools, you can achieve complete accuracy in your inventory counts.

RFID reader can streamline asset scanning, eliminate human errors, and make cycle counting a snap. And it can also be used to track the quality of a product. Using this technology, you can get a more accurate idea of the condition of an item, which is especially useful in the case of wine.

While it may take some time for RFID to become a mainstream solution, it’s a good idea to start thinking about it now. Having an accurate and up-to-date inventory will be essential for an efficient supply chain in the future.

RFID readers are inexpensive

RFID is a fast-growing technology for inventory management. It’s a faster and easier way to count and track items and can help you avoid stockouts.

While RFID isn’t inexpensive, there are some ways to keep costs down. A company’s specific needs, infrastructure, and the amount of data they want to capture are all factors to consider.

An RFID reader is a network-connected device that scans tags or RFID inlay. The reader can be a handheld or a fixed model, and the technology can check items in or out of stock. Depending on the system, you can expect to spend anywhere from one thousand to ten thousand dollars for a reader.

A combination of a fixed and handheld reader is the most common for most retail organisations. It allows you to perform various tasks, such as automating reordering, minimising cycle counts, and providing insight into the most valuable items.

There are many other benefits to using RFID, including streamlined processes, better visibility, and reduced labour costs. Although an RFID system can be a significant investment, the benefits can outweigh the cost.

As you consider your options, be sure to read the newest and latest news about the technology. For example, some businesses now use RFID to streamline inventory processing and improve customer service.

Whether you’re considering a handheld or fixed reader, the best way to determine if an RFID solution is right for your business is to look at your current processes. Then, if you still need to use RFID technology, you could miss valuable information about your customers and inventory.

Combining a mobile RFID reader and a fixed reader can give you an all-in-one solution for your inventory management. For example, you can use this technology to count items as you store them or set up a schedule for restocking items.